APPLICATION

Contact:Mr.Kwan

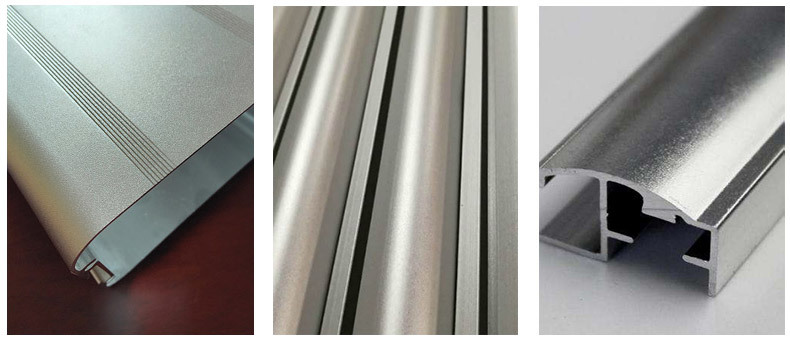

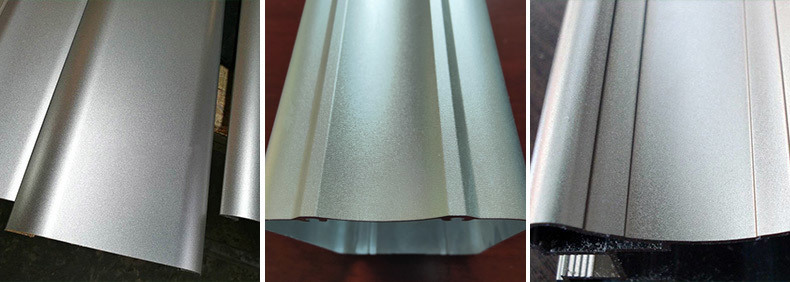

Sandblasting area for aluminum profiles.

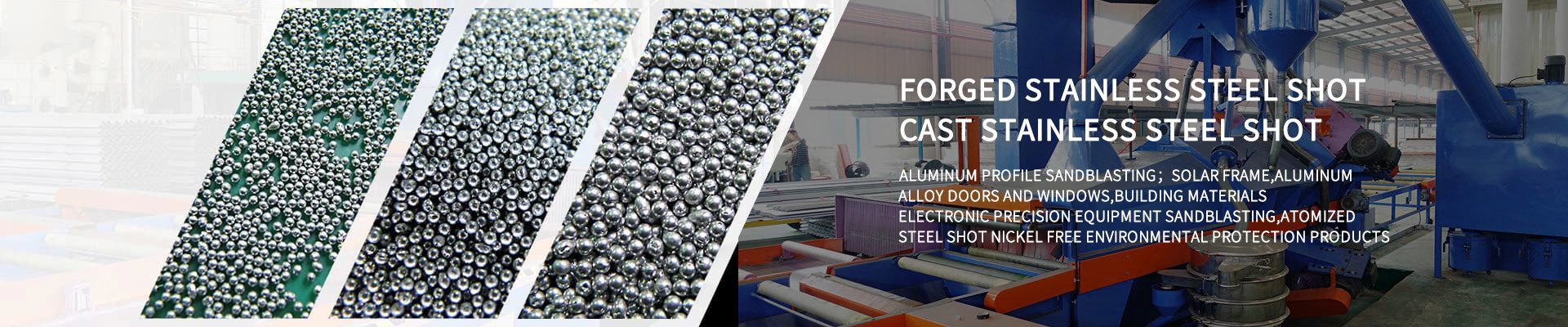

Yuefeng Abrasive Co., Ltd. focuses on the research and development and production of special stainless steel shots (stainless steel sand) for aluminum blasting, which is widely used in domestic major aluminum profile companies. According to the customer's requirements for the surface of aluminum, we can provide high-quality door-to-door sand surface deployment and improve the surface gloss of aluminum, and provide customers with a set of solutions to solve the lack of aluminum surface gloss and blackening.

Our company can specially customize stainless steel shots (stainless steel sand) for aluminum profiles according to customer needs, 0.05-0.15mm, 0.1-0.2mm, 0.15-0.25mm, and special sizes can be customized for customers. Yuefeng Stainless Steel shot is an ideal choice for sandblasting of various porcelain swimming profiles, photovoltaic solar frames, and building materials.

Our company's special stainless steel shots for stainless steel (stainless steel sand) have less dust, which can effectively avoid the problems of dusty glass like glass sand and difficult to recruit jobs. Yuefeng reinforced stainless steel shots meet environmental requirements and have a long service life and effectively reduce sand blast cost.

Advantages of Yuefeng nickel-free reinforced stainless steel shot

The reinforced stainless steel shot produced by forging technology has a dense surface density and high integrity, which makes its average service life (loss) reach 0.8-1.0KG / ton aluminum profile, which is an ideal environmentally friendly dust-free blasting material.

The high-quality production distribution ratio makes it almost the same as the blasting effect of similar imported stainless steel shots (stainless steel sand), with higher cost performance, and has replaced imported similar products.

The surface of the aluminum profile after sand blasting is bright, reaching the original color of the metal, which is beautiful.

Advantages of Yuefeng nickel-free reinforced stainless steel shot

The particles are round and smooth, with a longer service life, less dust, and a short transition period, which is more in line with environmental protection requirements. Compared with imported nickel-free stainless steel shots, the sandblasting effect is equivalent and the cost performance is higher.