NEWS/

Contact:Mr.Kwan

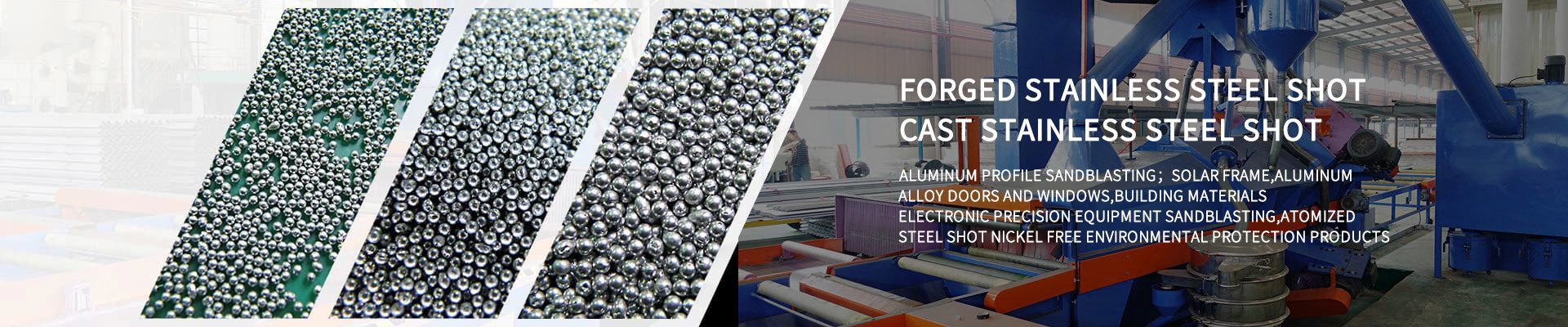

Introduction to the use of media for sand blasting on the surface of aluminum profiles

In the aluminum profile industry, the sandblasting media can be divided into two categories. The first category is glass sand and the second type is stainless steel pellets. For environmental protection reasons, most companies have abandoned glass sand and used stainless steel pellets as sandblasting media. Stainless steel pellets are produced by two different production processes. Stainless steel pellets produced by different processes are suitable for aluminum sandblasting. The first type is produced by melt casting, and the production process is ablation by nitrogen (hereinafter referred to as "atomized stainless steel pellets". The second type is produced in the form of forging. The production process is made of high-hardness stainless steel wire and cut into granules. After deep processing and rounding, it is referred to as [reinforced stainless steel pill].

The atomized stainless steel pellets used to rely on imported products in the past, but in recent years, the domestic production of stainless steel pellets by atomization method is also very common. Because of the increasing number of manufacturers, the quality is also uneven. [Strengthened stainless steel pill] has been in the domestic market for more than 10 years. Most of the products are applied to aluminum die-casting blasting, and aluminum die-casting parts are sandblasted with large-sized steel shots. The sand surface of the aluminum profile is required to be high, and the sandblasting medium is used in a relatively fine manner. It is difficult to make a steel ball of 0.1 such a fine steel wire with a cut wire. The manufacturer must have high-precision production equipment to complete the process. Therefore, the manufacturers of the shredded pill industry are not willing to try to produce. Even if the individual can complete the process of cutting the wire, the most difficult part is the sorting of the finished product. It is necessary to separate the wire segments that are contained in the product. The finished pellets rate is 100%, and such a screening selection technique is more difficult to pour all the shredded pill manufacturers.

however! [Jiangmen Xinhui District Yuefeng Abrasive Co., Ltd.] solved all technical difficulties in the production of profile blasting by forging method, and successfully developed stainless steel pill with high wear resistance and low loss rate of 100%. Those who know how to know know that the precision and mass density of stainless steel pellets produced by forging are higher than that of atomized stainless steel pellets. The atomized stainless steel pellets have shortcomings such as pores and hollow pellets. They are easily broken during use and greatly shorten the service life of steel pellets. The reinforced stainless steel pill has good toughness, impact resistance, non-breaking, low loss and less dust. The stainless steel pill produced by forging can maintain the primary color of stainless steel, so the surface of the aluminum profile will be whiter after being oxidized by reinforced stainless steel pill.

Key words:

Sand blasting

Related News